Study, design and installation with a single partner

Industrial quality production

Products developed and produced in our workshops in the Moselle region of France

SPECIFIC INDUSTRIAL PROCESS EQUIPMENT

Coutier is your industrial partner for applications dedicated to industrial manufacturing processes. We are present in many sectors with our 3 skill centres (automotive, equipment manufacturers, aeronautics, rail, food industry, steel industry, etc.)

All our products are developed by our integrated design office which collaborates closely with our clients to propose THE solutions that solve the issues encountered and guarantee the expected performance. Our services range from the design and production of a single prototype to mass production.

Our turnkey service is also accompanied, on request, by on-site integration and installation of the proposed equipment by our specialised assembly teams.

INTRA-LOGISTICS SUPPLIES

Great adaptability to your needs: Rolling bases with fixed, rotating or tilting platform, intra-logistics handling equipment…

Supply chain and continuous improvement expertise

Reliability, safety and comfort of use

Significant productivity gains

Over 10,000 systems in use

Unit and mass production

The supply chain management of production lines in factories increasingly requires the use of trains of rolling bases and milk run carts.

This equipment is dedicated to the most commonly used packaging in industry and allows the optimisation of just-in-time production lines.

This concept replaces the use of many forklifts in the vicinity of the operators which generate accident risks.

Coutier also designs and manufactures all intra logistics handling equipment specifically developed for the type of parts to be transported and the workstation configuration:

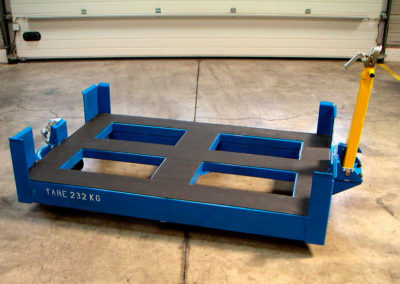

- fixed, tilting or rotating bases on wheels

- kitting carts

- kanban carts

- picking carts

- elevator tables

- pivoters

- tippers

- trailers

- gravity and motorised conveyors…

- dollies and mother-dollies

For comfort at work and in compliance with ergonomic requirements, these carts and rolling bases can be fitted with a motorised wheel to assist movement and run with our indexing station system to guarantee their line side positioning.

Rolling bases with handrails on an assembly line of an automotive production site – Spain

Fixed Tray Rolling Base

Loading a rolling base with a forklift – automotive production site – Moselle (57)

Loading a rolling base

Mother dolly rolling base, with lockable compartments for loading four dollies – Moselle (57)

Rolling base type “mother dolly”

Rolling bases with six wheels and single tray, Coutier drawbars and ring drawbars

Multi-container rolling bases

Rolling bases for supplying assembly lines with steering racks for an automobile production site – Ille et Vilaine (35)

Rolling bases transport steering bars

LINE SIDE HANDLING AND SPECIAL MACHINES

Development of tailored solutions

Turnkey services (study, design, production, implementation on site)

Reliability, safety and comfort of use

Significant productivity gains

Regardless of our customers’ sector of activity, their production lines require the installation of handling resources to transfer components between workstations:

- Lifting equipment: rolling beams, jib cranes, hoists, drop benches, etc.

- Overhead handling equipment: swing trays, conveyors, etc.

- Ground handling equipment: conveyors, robot line frames, roller tables, mobile transfer platforms, risers, tippers, pivoters, line side units, etc.

- Complete integration and fitting out of small production lines: furniture, work floors, handling equipment, etc.

Our products are adapted to the configurations encountered and also take into account the constraints related to the geometry of the equipment to be handled, while respecting the ergonomic requirements of continuous improvement departments.

Conveyor for discs and hubs on assembly line of automotive production site – Nord (59)

Conveyor for discs and hubs

Assembly of a lifting table for rear axles, automobile production site – Nord (59)

Installation of a lifting table

SPECIAL TOOLS

Development of innovating tailored solutions

Significant productivity gains

Return on investment: less than one year

Reduction in the non-quality of manufactured openings

Maintenance-free tooling

Coutier is present at car manufacturers in the design and manufacture of specific tools dedicated to holding openings (bonnets, tail gates, doors, fuel hatches, …) in the various positions of the surface treatment process with a specialisation in tools for sliding doors. In addition, we also produce a range of swing trays adapted to the shape of the parts to be transported on conveyors.

Our innovating project management approach for each developed tool or range of tools encompasses the formulation of customer requirements, development, prototyping and pre-production, production and life cycle testing of the vehicle, whilst respecting dimensional accuracy requirements.

Our solutions bring a substantial gain in productivity through the intensive reuse of tools without repeated maintenance and guarantee the precision of the positioning of the openings in relation to the structure of the vehicle, a source of manufacturing and assembly quality…

Swing for the supply of openings on the assembly line, automotive production site – Yvelines (78)

Swing – assembly line

Platforms for transporting vehicles on an automobile production site – Moselle (57)

Swings for transporting vehicles

Sliding side door support tool for utility treatment baths – Meurthe-et-Moselle (54)

Sliding side door support tool